The day past, Tesla inventory closed at a worth in line with proportion of $188.18, and whilst that’s down from the corporate’s 52-week top of $299.19, it nonetheless makes Tesla extra precious than the following 4 most beneficial automotive corporations mixed – Toyota, Porsche, Mercedes-Benz and BYD. However it wasn’t at all times that method. After I began at Tesla as worker quantity 350 in November, 2009, the corporate used to be severely suffering financially. We have been dwelling hand to mouth, which isn’t surprising from a small start-up. Nonetheless, in spite of our dimension, we have been bold. We had simply began the design segment of the Style S and we had top hopes for the automobile, however a low finances.

It’ll sound sudden as of late, however Tesla didn’t have billions within the financial institution again then, and growing a brand new automotive is an overly pricey proposition. It takes loads of thousands and thousands of greenbacks to design, expand, and gear up a brand new car. Simply to offer standpoint, when Ford advanced the brand new Taurus in 1986, it spent $2 Billion. 25 years later, the prices had most effective long past up from there.

![]()

![]()

So at Tesla, we needed to get inventive to save cash anywhere shall we. You’ll be able to see the results of this within the chassis, particularly within the steerage machine and rear suspension.

Right here’s a video the place I provide an explanation for all of this:

Steerage Racks Are Absurdly Pricey

Symbol: TRW

Symbol: TRW

One of the pricey portions of a automotive’s suspension machine is the steerage tools. Designing and tooling a brand new steerage tools can value smartly over a $one million. The housing is a fancy casting, and the rack bar (an instance of which is proven underneath) is an overly sophisticated forging requiring some very fancy tooling to create the enamel and the helical groove for the electrical energy help machine.

Symbol by way of: Electrical steerage rack bar Ford Explorer с 2012-2015 LESS AUTOMATED PARKING SYSTEM (motorherz.us)

Symbol by way of: Electrical steerage rack bar Ford Explorer с 2012-2015 LESS AUTOMATED PARKING SYSTEM (motorherz.us)

Even within the previous days of hydraulic steerage methods, steerage gears have been pricey to make. There used to be no method a small start-up corporate like Tesla would be capable to have the funds for this type of massive invoice. On most sensible of that, Tesla used to be an unproven corporate. We didn’t have a protracted historical past of profitability and good fortune but. For plenty of conventional providers, agreeing to design and expand one thing as advanced and dear as a steerage tools would were a significant possibility they have been unwilling to take.

The way in which round this is to discover a steerage tools that already exists which the provider and the present proprietor will conform to can help you use. If you happen to’re fortunate, yow will discover a steerage tools that matches completely, and the place the provider has sufficient further manufacturing capability to reinforce your wishes. Manufacturing capability used to be not going to be an issue for many providers since, on the time, we have been most effective anticipating to promote about 20,000 Style S’s in line with yr. However discovering simply the correct tools used to be going to be a hard activity.

You’ll be able to’t simply move as much as any other automotive corporate and ask them for the main points on all their steerage gears to peer which one may be just right for you. No person’s going to even resolution the telephone. You’ll be able to go away a message however don’t be expecting to listen to again from them.

The solution used to be to paintings throughout the providers. Thankfully, ZF-Lenksysteme, a well known German steerage provider, agreed to paintings with us so long as we have been in a position to seek out one thing of their present manufacturing catalog that may go well with us.

Step one on this procedure used to be to decide what we in reality wanted. We did this through designing a entrance suspension whilst pretending that shall we get no matter we needed. We created a entrance suspension design we preferred, and which would slot in our automotive. Out of that procedure got here two essential numbers – the period of the steerage rack, and one thing referred to as the C-factor.

What We Have been Taking a look For: Rack Period

The period of the rack is the gap between the left and correct internal tie rod joints. This size is fastened through the period of the rack bar and through the design of the steerage tools housing and will require an entire redesign of the steerage tools so as to exchange.

The explanation this size is so necessary is that the location of the interior tie rod joint relative to the higher and decrease keep watch over arm internal bushings establishes how the wheel will steer because the suspension strikes up and down (the interior tie rod swings up and down, and so does the keep watch over arm; the adaptation within the arcs on the finish of the ones “swings” has large dealing with implications; this phenomenon is named “roll steer.”). If the rack period is just too lengthy, i.e., the location of the interior tie rod ends is just too a long way outboard, then the period of the tie rods shall be too quick relative to the keep watch over hands and within the suspension proven above, the wheels will steer inward (toe in) as they transfer up or down. The other will occur if the rack is just too quick and the interior tie rod ends are too a long way inboard.

In fact, the vertical and fore/aft place of the interior tie rod also are essential to the correct functioning of the suspension, however this may also be simply modified through transferring all the steerage tools up/down or fore/aft. There’s no option to adjust the inboard/outboard place of the interior tie rod joint as soon as the period of the steerage tools has been established.

C-Issue

The opposite size this is essential to the serve as of the steerage rack is named the C-factor, and it refers back to the distance the rack travels right through one complete revolution of the steerage wheel. This quantity is normally within the 45-65 mm/rev vary, and it determines how briskly the steerage feels. A better quantity method the rack strikes extra for each and every flip of the wheel and so the steerage will really feel faster than if the C-factor is a decrease quantity.

The C-factor wanted for a selected steerage tools is made up our minds through an research of the total steerage ratio, which is the ratio between the levels of steerage wheel rotation in comparison to the levels of steerage on the entrance wheels. For many passenger automobiles, this quantity is at the order of 14-17:1, that means for each and every 14-17 levels the steerage wheel turns, the entrance wheels will steer 1 stage.

We Discovered A Land Rover Rack That Would Paintings, However It Used to be Proper-Hand Pressure

When we had established what steerage tools we needed, it used to be then an issue of seeing what used to be in manufacturing that could be shut. We supplied our necessities to ZF-Lenksysteme, and so they temporarily made up our minds {that a} rack they have been quickly to position into manufacturing for the Land Rover Evoque used to be very shut. Right here’s the Evoque right-hand-drive rack:

Symbol: eurojag123/eBay

Symbol: eurojag123/eBay

And here’s a rack from a Style S:

Symbol: 1ofdabest/eBay

Symbol: 1ofdabest/eBay

You’ll be able to see how they’re similar with the exception of for the ends of the tie rods (those are relatively affordable to software), which needed to be other to hook up with our knuckle.

We must perform a little minor adjustments to our suspension design to make it are compatible, however those can be simple to do and wouldn’t compromise the capability of our design. The most important drawback used to be that the Land Rover tools used to be designed to be positioned in the back of the centerline of the axle (referred to as “rear steer,” to not be perplexed with rear axle steer) whilst we needed to position ours forward of the axle centerline (referred to as “entrance steer”). The issue is that gears designed to be positioned in entrance or in the back of the axle transfer in reverse instructions. In a rack designed for entrance steer, the rack will transfer to the correct while you flip the wheel to the correct whilst in a rack designed for rear steer, the rack will transfer to the left while you flip the wheel to the correct.

Obviously, we couldn’t merely take the Land Rover rack and position it into our suspension design. The auto would steer to the left while you became the wheel to the correct!

Our resolution used to be to make use of the right-hand power rack from the Land Rover, turn it the other way up (so the correct aspect used to be now at the left and vice versa, and the ground mounts that typically connect to the subframe are actually pointing up), and position it in entrance of our axle for our left-hand power software. Flipping the rack had the impact of reversing the path the rack would trip, that means it will now transfer in the right kind path while you became the wheel and it additionally had the impact of transferring the pinion, the place the steerage wheel and column connect, from the correct aspect to the left aspect of the car. This became the Land Rover right-hand power rear steer rack right into a left-hand power entrance steer rack that shall we use.

That left most effective two issues for us to do, or so we idea.

The primary used to be to determine learn how to connect the rack to our car construction. Flipping the rack over intended that the bolts that fixed the rack would now finally end up at the most sensible aspect of the housing and a long way clear of our construction. The answer used to be so as to add two towers to the entrance subframe that reached up top sufficient to get to the bolts.

The second one factor left to do used to be negotiate a industrial association with Land Rover that may let them conform to allow us to use the steerage tools they paid for, made with the tooling they bought. Thankfully, we had some very good negotiators on our staff, and we got here to a mutually really helpful settlement.

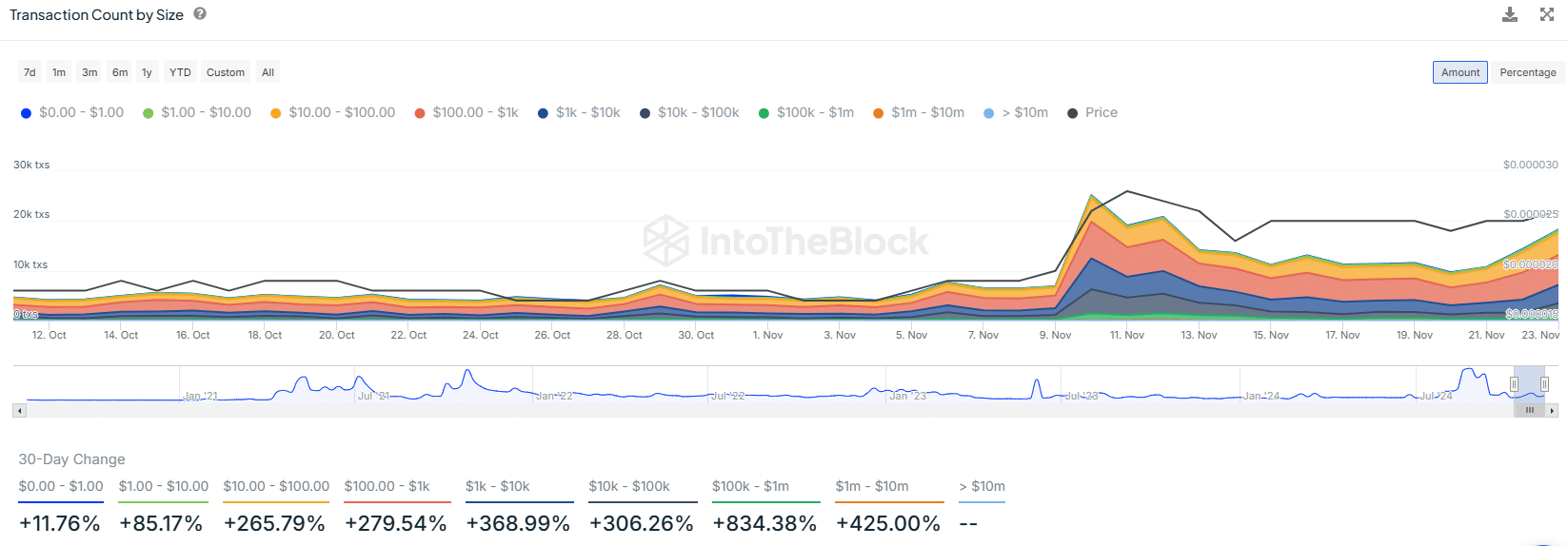

Every other Downside: The Land Rover’s Steerage Rack Used to be Too ‘Fast’

Whilst the period of the Evoque rack used to be shut sufficient that shall we use it, the C-factor used to be relatively a little bit upper than we needed. We knew we may have a subject, however we idea shall we most likely are living with it. After we constructed our first prototypes on the other hand, we temporarily came upon that the steerage used to be a lot too fast.

The auto used to be darty and hard to power at the freeway. It wasn’t stress-free in any respect and can be uncomfortable for our consumers. Since converting the C-factor of the rack intended designing and tooling a brand new rack bar and pinion, we needed to in finding differently of constructing the steerage really feel slower. Our resolution used to be to switch the roll understeer of the entrance suspension.

How Suave Engineering ‘Canceled’ Out The Land Rover’s Overly-Fast Steerage Rack

Roll understeer (which David describes within the Instagram video above) is a feature of a suspension design that forces the wheels to persuade within the path reverse to the steerage enter when the car frame rolls in a flip. In maximum automobiles, each the entrance and rear suspensions are designed to have some nominal quantity of roll understeer. This is the way it works.

Let’s say we’re creating a left flip. We flip the steerage wheel to the left which turns the entrance wheels to the left. Because the car enters the flip, the frame will roll to the correct which strikes the right-side suspension reasonably upward and the left aspect reasonably downward. Because the right-side suspension strikes up, the roll understeer forces the correct entrance wheel to persuade reasonably to the correct, successfully subtracting one of the steerage we installed on the steerage wheel. The suspension in reality steers a small quantity lower than we requested for. It “beneath” steers a bit.

The quantity of steerage we get because the frame rolls is managed through the suspension design. Let’s take an instance entrance suspension:

When seen from the entrance:

you’ll be able to see the higher and decrease keep watch over hands in addition to the tie rod and, in each and every case, the arcs each and every will hint because the suspension strikes up and down. On this design, the arcs are all very identical, so the 3 hands will transfer quite parallel to one another. However what if we moved the outer tie rod finish down like this?

Now we see that the arc the outer tie rod finish follows because the wheel strikes up and down is tilted relative to the higher and decrease ball joint arcs. Because of this because the wheel strikes up, the outer tie rod finish will transfer outward (i.e it’s going to “prolong”) whilst the higher and decrease ball joints are simply transferring roughly directly up. Because the steerage rack and tire rod are fixed in entrance of the axle centerline on this design, the impact shall be to persuade the wheel outward because it strikes up and inward because it strikes down.

By means of transferring the outer tie rod finish down, we’ve got modified the best way the wheel steers because it strikes up and down. By means of various the volume we transfer the outer tie rod up or down relative to the higher and decrease ball joints, we will exchange the volume of steer we get right through wheel motion. That is how we alter the volume of roll understeer our suspension has.

And that’s precisely what we did at the authentic Style S. We moved the outer tie rod down so as to building up the volume of roll understeer. Successfully, we used the roll of the frame right through a flip to subtract from the volume of steerage we requested for on the steerage wheel which had the impact of slowing the steerage right down to a degree we felt can be appropriate to our consumers.

Saving Cash By means of Flipping Regulate Fingers, Sensible Production

The usage of an present steerage tools wasn’t the one we attempted to save lots of value within the Style S suspension. One of the pricey portions of a suspension design are the gear had to make the keep watch over hands, particularly if the ones portions are cast. Forging gear can value many loads of hundreds of greenbacks relying on how advanced the section is. If we will use fewer gear, then the overall invoice shall be that a lot decrease. A very easy method to try this is to make use of attempt to use not unusual portions at the left and correct aspect. That method, you wish to have a unmarried software the place you another way would have wanted two. In lots of circumstances this simply isn’t imaginable. A knuckle, as an example, is sort of inconceivable to make the similar at the left and correct aspect. I’ve noticed it performed however in my view it severely compromises the design.

However in different circumstances, it may be performed. The lateral hyperlink within the Style S entrance suspension is a superb instance. This section is similar on each the left and correct facets.

The rear suspension is the place we have been in a position to actually put this philosophy to excellent use. Whilst the rear knuckles are distinctive left to correct, the entire different suspension portions are not unusual. Even the large decrease hyperlink is similar left and correct. The left aspect is just the right-side section flipped over.

This hyperlink is in reality relatively advanced since this is a hole casting. Hole castings use a sand core positioned within a metal mildew leaving a small hole everywhere in the edges the place the molten aluminum is poured. As soon as the aluminum solidifies and the section is got rid of from the mildew, the sand is trapped throughout the section. It’s then got rid of through shaking it violently so the sand falls aside and is poured out thru a big hollow left for that objective. As soon as the entire sand is long past, the outlet is plugged or in some circumstances merely left open.

The knuckles are same old aluminum castings, not anything particular there, however the different hyperlinks have been made in some way that still stored us some huge cash. They’re extrusions.

This video does a excellent process of explaining what extrusions are and the way they’re made:

I discussed previous that forging gear are extraordinarily pricey and whilst gear to make aluminum castings are so much inexpensive, they’re nonetheless relatively pricey. Extrusion gear, through comparability, are extraordinarily affordable. The die to make the small integral hyperlink most effective value a couple of thousand greenbacks whilst the die to make the higher hyperlink used to be at the order of 3-4 instances that a lot. And because each and every of those portions is not unusual at the left and correct facets, it intended one set of dies for either side of the suspension. A vital financial savings.

The usage of Commonplace Portions Left-Proper And Borrowing The Land Rover Rack Used to be Necessary

It’ll appear counter-intuitive to assume {that a} automotive as pricey because the Tesla Style S will require us to be so serious about value, however when you’re a start-up corporate with restricted price range, each and every penny counts. The Style S used to be and stays a dear automotive, so its capability needed to be at a commensurately top stage. Reaching that with the suspension intended getting inventive and saving value anywhere shall we whilst nonetheless turning in the efficiency. It used to be a amusing problem.