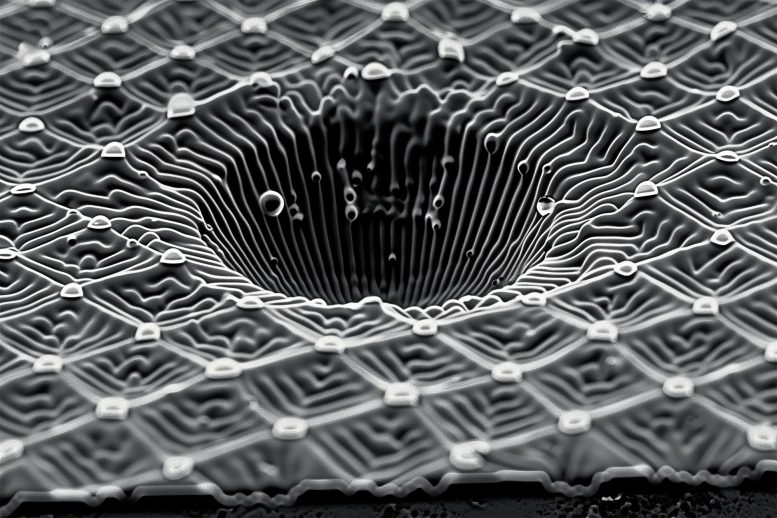

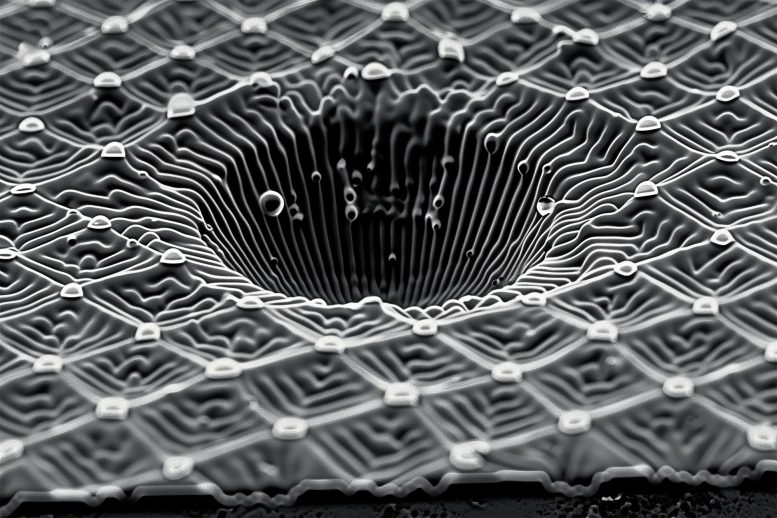

Metamaterials with explicit microstructures outperform forged fabrics in resisting supersonic affects, providing attainable for complex protecting answers. (Artist’s thought.) Credit score: SciTechDaily.comHigh-speed experiments can assist establish light-weight, protecting “metamaterials” for spacecraft, cars, helmets, or different items.An intricate, honeycomb-like construction of struts and beams may just resist a supersonic impression higher than a forged slab of the similar subject material. What’s extra, the particular construction issues, with some being extra resilient to affects than others.That’s what MIT engineers are discovering in experiments with microscopic metamaterials — fabrics which might be deliberately published, assembled, or in a different way engineered with microscopic architectures that give the whole subject material outstanding houses.In a find out about revealed lately within the Court cases of the Nationwide Academy of Sciences, the engineers document on a brand new strategy to temporarily check an array of metamaterial architectures and their resilience to supersonic affects.

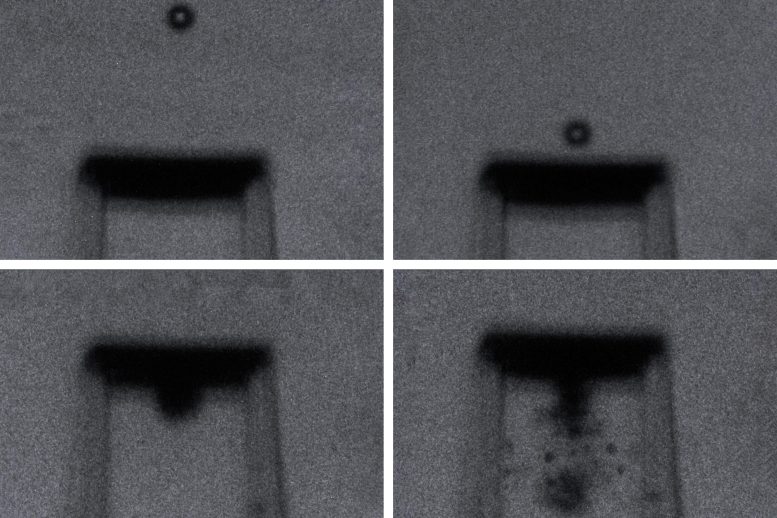

Metamaterials with explicit microstructures outperform forged fabrics in resisting supersonic affects, providing attainable for complex protecting answers. (Artist’s thought.) Credit score: SciTechDaily.comHigh-speed experiments can assist establish light-weight, protecting “metamaterials” for spacecraft, cars, helmets, or different items.An intricate, honeycomb-like construction of struts and beams may just resist a supersonic impression higher than a forged slab of the similar subject material. What’s extra, the particular construction issues, with some being extra resilient to affects than others.That’s what MIT engineers are discovering in experiments with microscopic metamaterials — fabrics which might be deliberately published, assembled, or in a different way engineered with microscopic architectures that give the whole subject material outstanding houses.In a find out about revealed lately within the Court cases of the Nationwide Academy of Sciences, the engineers document on a brand new strategy to temporarily check an array of metamaterial architectures and their resilience to supersonic affects. By means of firing microparticles at supersonic speeds, MIT engineers can check the resilience of quite a lot of metamaterials produced from buildings as small as a pink blood mobile. Pictured are 4 video stills of a microparticle hitting a construction manufactured from metamaterials. Credit score: Courtesy of the researchersIn their experiments, the workforce suspended tiny published metamaterial lattices between microscopic give a boost to buildings, then fired even tinier debris on the fabrics, at supersonic speeds. With high-speed cameras, the workforce then captured pictures of each and every impression and its aftermath, with nanosecond precision.Their paintings has known a couple of metamaterial architectures which might be extra resilient to supersonic affects in comparison to their fully forged, nonarchitected opposite numbers. The researchers say the effects they noticed on the microscopic degree will also be prolonged to related macroscale affects, to expect how new subject material buildings throughout duration scales will resist affects in the true international.

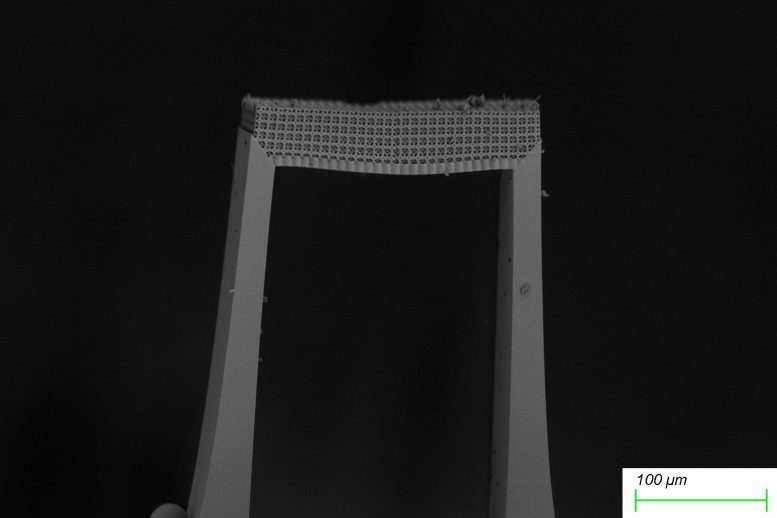

By means of firing microparticles at supersonic speeds, MIT engineers can check the resilience of quite a lot of metamaterials produced from buildings as small as a pink blood mobile. Pictured are 4 video stills of a microparticle hitting a construction manufactured from metamaterials. Credit score: Courtesy of the researchersIn their experiments, the workforce suspended tiny published metamaterial lattices between microscopic give a boost to buildings, then fired even tinier debris on the fabrics, at supersonic speeds. With high-speed cameras, the workforce then captured pictures of each and every impression and its aftermath, with nanosecond precision.Their paintings has known a couple of metamaterial architectures which might be extra resilient to supersonic affects in comparison to their fully forged, nonarchitected opposite numbers. The researchers say the effects they noticed on the microscopic degree will also be prolonged to related macroscale affects, to expect how new subject material buildings throughout duration scales will resist affects in the true international. The researchers print intricate, honeycomb fabrics, suspended between supporting pillars of the similar subject material (pictured). The microscopic construction is as tall because the width of 3 human hairs. Credit score: Courtesy of the researchers“What we’re studying is, the microstructure of your subject material issues, even with high-rate deformation,” says find out about writer Carlos Portela, the Brit and Alex d’Arbeloff Profession Building Professor in Mechanical Engineering at MIT. “We wish to establish impact-resistant buildings that may be made into coatings or panels for spacecraft, cars, helmets, and the rest that must be light-weight and secure.”Different authors at the find out about come with first writer and MIT graduate pupil Thomas Butruille, and Joshua Crone of DEVCOM Military Analysis Laboratory.Natural ImpactThe workforce’s new high-velocity experiments construct off their earlier paintings, through which the engineers examined the resilience of an ultralight, carbon-based subject material. That subject material, which used to be thinner than the width of a human hair, used to be produced from tiny struts and beams of carbon, which the workforce published and put on a tumbler slide. They then fired microparticles towards the fabric, at velocities exceeding the rate of sound.The ones supersonic experiments published that the microstructured subject material withstood the high-velocity affects, now and again deflecting the microparticles and different instances shooting them.“However there have been many questions we couldn’t resolution as a result of we have been trying out the fabrics on a substrate, which could have affected their habits,” Portela says.

The researchers print intricate, honeycomb fabrics, suspended between supporting pillars of the similar subject material (pictured). The microscopic construction is as tall because the width of 3 human hairs. Credit score: Courtesy of the researchers“What we’re studying is, the microstructure of your subject material issues, even with high-rate deformation,” says find out about writer Carlos Portela, the Brit and Alex d’Arbeloff Profession Building Professor in Mechanical Engineering at MIT. “We wish to establish impact-resistant buildings that may be made into coatings or panels for spacecraft, cars, helmets, and the rest that must be light-weight and secure.”Different authors at the find out about come with first writer and MIT graduate pupil Thomas Butruille, and Joshua Crone of DEVCOM Military Analysis Laboratory.Natural ImpactThe workforce’s new high-velocity experiments construct off their earlier paintings, through which the engineers examined the resilience of an ultralight, carbon-based subject material. That subject material, which used to be thinner than the width of a human hair, used to be produced from tiny struts and beams of carbon, which the workforce published and put on a tumbler slide. They then fired microparticles towards the fabric, at velocities exceeding the rate of sound.The ones supersonic experiments published that the microstructured subject material withstood the high-velocity affects, now and again deflecting the microparticles and different instances shooting them.“However there have been many questions we couldn’t resolution as a result of we have been trying out the fabrics on a substrate, which could have affected their habits,” Portela says. MIT engineers have captured video of a microparticle being fired via a exactly architected metamaterial, measuring thinner than the width of a human hair. Credit score: Courtesy of the researchersIn their new find out about, the researchers evolved a strategy to check freestanding metamaterials, to watch how the fabrics resist affects purely on their very own, with no backing or supporting substrate.Of their present setup, the researchers droop a metamaterial of hobby between two microscopic pillars produced from the similar base subject material. Relying at the dimensions of the metamaterial being examined, the researchers calculate how some distance aside the pillars will have to be so as to give a boost to the fabric at both finish whilst permitting the fabric to answer any affects, with none affect from the pillars themselves.“This fashion, we make sure that we’re measuring the fabric assets and no longer the structural assets,” Portela says.As soon as the workforce settled at the pillar give a boost to design, they moved on to check plenty of metamaterial architectures. For each and every structure, the researchers first published the supporting pillars on a small silicon chip, then persevered printing the metamaterial as a suspended layer between the pillars.“We will be able to print and check loads of those buildings on a unmarried chip,” Portela says.Punctures and CracksThe workforce published suspended metamaterials that resembled intricate honeycomb-like cross-sections. Every subject material used to be published with a particular third-dimensional microscopic structure, comparable to an actual scaffold of repeating octets, or extra faceted polygons. Every repeated unit measured as small as a pink blood mobile. The ensuing metamaterials have been thinner than the width of a human hair.The researchers then examined each and every metamaterial’s impression resilience via firing glass microparticles towards the buildings, at speeds of as much as 900 meters in step with 2d (greater than 2,000 miles in step with hour) — smartly throughout the supersonic vary. They stuck each and every impression on digicam and studied the ensuing pictures, body via body, to peer how the projectiles penetrated each and every subject material. Subsequent, they tested the fabrics beneath a microscope and when compared each and every impression’s bodily aftermath.“Within the architected fabrics, we noticed this morphology of small cylindrical craters after impression,” Portela says. “However in forged fabrics, we noticed numerous radial cracks and larger chunks of subject material that have been gouged out.”Total, the workforce noticed that the fired debris created small punctures within the latticed metamaterials, and the fabrics however stayed intact. By contrast, when the similar debris have been fired on the identical speeds into forged, nonlatticed fabrics of equivalent mass, they created massive cracks that temporarily unfold, inflicting the fabric to collapse. The microstructured fabrics, subsequently, have been extra environment friendly in resisting supersonic affects in addition to protective in opposition to more than one impression occasions. And particularly, fabrics that have been published with the repeating octets gave the impression to be essentially the most hardy.Observations and Long run Instructions“On the identical speed, we see the octet structure is more difficult to fracture, which means that the metamaterial, in step with unit mass, can resist affects as much as two times up to the majority subject material,” Portela says. “This tells us that there are some architectures that may make a subject material harder which will be offering higher impression coverage.”Going ahead, the workforce plans to make use of the brand new fast trying out and research approach to establish new metamaterial designs, in hopes of tagging architectures that may be scaled as much as more potent and lighter protecting tools, clothes, coatings, and paneling.“What I’m maximum thinking about is appearing we will be able to do numerous those excessive experiments on a benchtop,” Portela says. “This will likely considerably boost up the speed at which we will be able to validate new, high-performing, resilient fabrics.”Reference: “Decoupling particle-impact dissipation mechanisms in 3-d architected fabrics” via Thomas Butruille, Joshua C. Crone and Carlos M. Portela, 2 February 2024, Court cases of the Nationwide Academy of Sciences.

MIT engineers have captured video of a microparticle being fired via a exactly architected metamaterial, measuring thinner than the width of a human hair. Credit score: Courtesy of the researchersIn their new find out about, the researchers evolved a strategy to check freestanding metamaterials, to watch how the fabrics resist affects purely on their very own, with no backing or supporting substrate.Of their present setup, the researchers droop a metamaterial of hobby between two microscopic pillars produced from the similar base subject material. Relying at the dimensions of the metamaterial being examined, the researchers calculate how some distance aside the pillars will have to be so as to give a boost to the fabric at both finish whilst permitting the fabric to answer any affects, with none affect from the pillars themselves.“This fashion, we make sure that we’re measuring the fabric assets and no longer the structural assets,” Portela says.As soon as the workforce settled at the pillar give a boost to design, they moved on to check plenty of metamaterial architectures. For each and every structure, the researchers first published the supporting pillars on a small silicon chip, then persevered printing the metamaterial as a suspended layer between the pillars.“We will be able to print and check loads of those buildings on a unmarried chip,” Portela says.Punctures and CracksThe workforce published suspended metamaterials that resembled intricate honeycomb-like cross-sections. Every subject material used to be published with a particular third-dimensional microscopic structure, comparable to an actual scaffold of repeating octets, or extra faceted polygons. Every repeated unit measured as small as a pink blood mobile. The ensuing metamaterials have been thinner than the width of a human hair.The researchers then examined each and every metamaterial’s impression resilience via firing glass microparticles towards the buildings, at speeds of as much as 900 meters in step with 2d (greater than 2,000 miles in step with hour) — smartly throughout the supersonic vary. They stuck each and every impression on digicam and studied the ensuing pictures, body via body, to peer how the projectiles penetrated each and every subject material. Subsequent, they tested the fabrics beneath a microscope and when compared each and every impression’s bodily aftermath.“Within the architected fabrics, we noticed this morphology of small cylindrical craters after impression,” Portela says. “However in forged fabrics, we noticed numerous radial cracks and larger chunks of subject material that have been gouged out.”Total, the workforce noticed that the fired debris created small punctures within the latticed metamaterials, and the fabrics however stayed intact. By contrast, when the similar debris have been fired on the identical speeds into forged, nonlatticed fabrics of equivalent mass, they created massive cracks that temporarily unfold, inflicting the fabric to collapse. The microstructured fabrics, subsequently, have been extra environment friendly in resisting supersonic affects in addition to protective in opposition to more than one impression occasions. And particularly, fabrics that have been published with the repeating octets gave the impression to be essentially the most hardy.Observations and Long run Instructions“On the identical speed, we see the octet structure is more difficult to fracture, which means that the metamaterial, in step with unit mass, can resist affects as much as two times up to the majority subject material,” Portela says. “This tells us that there are some architectures that may make a subject material harder which will be offering higher impression coverage.”Going ahead, the workforce plans to make use of the brand new fast trying out and research approach to establish new metamaterial designs, in hopes of tagging architectures that may be scaled as much as more potent and lighter protecting tools, clothes, coatings, and paneling.“What I’m maximum thinking about is appearing we will be able to do numerous those excessive experiments on a benchtop,” Portela says. “This will likely considerably boost up the speed at which we will be able to validate new, high-performing, resilient fabrics.”Reference: “Decoupling particle-impact dissipation mechanisms in 3-d architected fabrics” via Thomas Butruille, Joshua C. Crone and Carlos M. Portela, 2 February 2024, Court cases of the Nationwide Academy of Sciences.

DOI: 10.1073/pnas.2313962121This paintings used to be funded, partially, via DEVCOM ARL Military Analysis Place of work throughout the MIT Institute for Soldier Nanotechnologies (ISN), and performed, partially, the usage of ISN’s and MIT.nano’s amenities.

Engineering the Unbreakable: MIT’s Microscopic Metamaterials Defy Supersonic Affects

/cdn.vox-cdn.com/uploads/chorus_asset/file/25803039/2190571551.jpg)