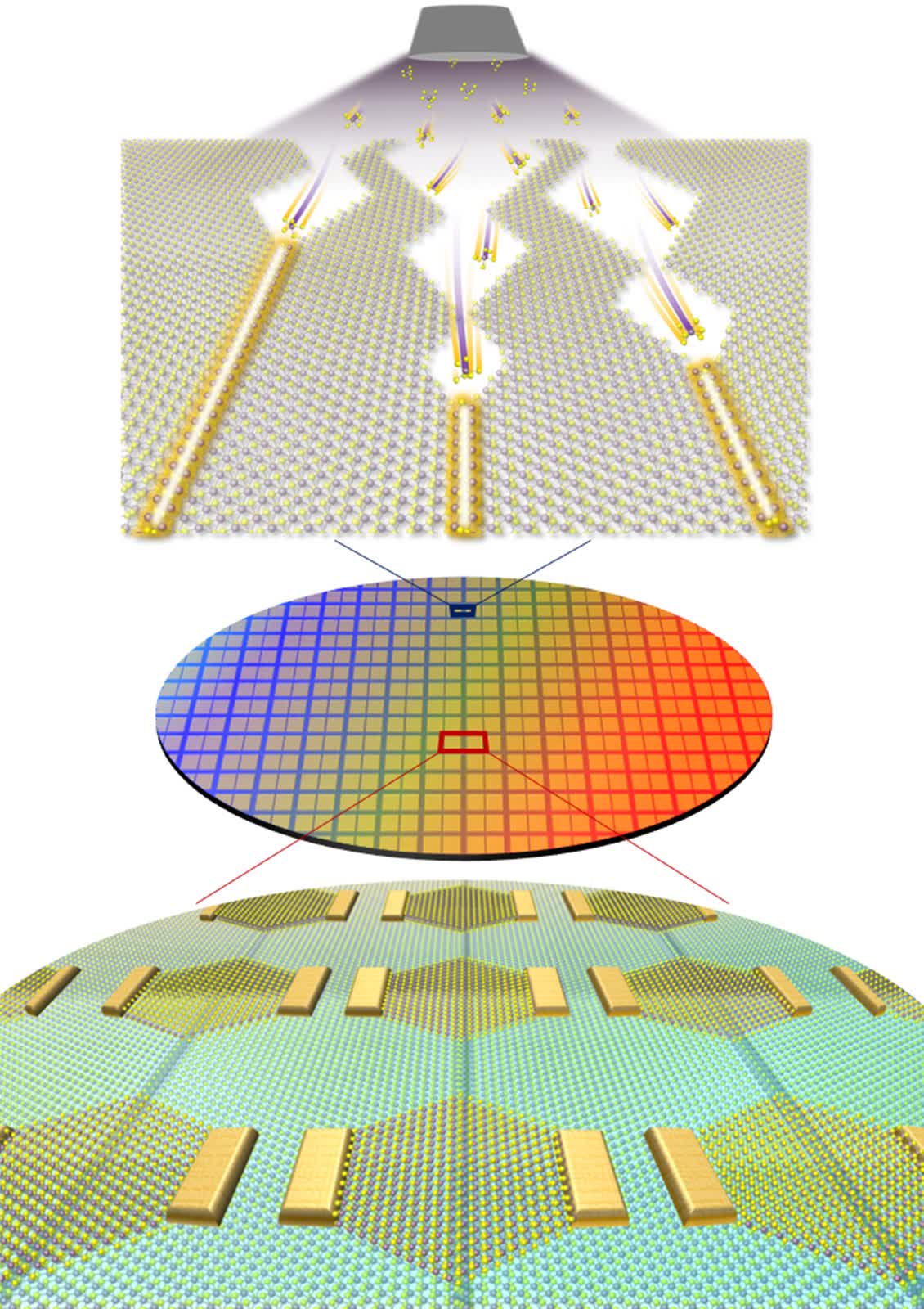

Why it issues: Moore’s Legislation will not be useless. A brand new approach of the use of nanomaterials can beef up transistors, permitting material grains to hold additional info on every chip. This analysis opens up new alternatives to create complex semiconductor gadgets that experience smaller dimensions than present generation lets in. A South Korean analysis crew led via Director Jo Moon-Ho of the Middle for Van der Waals Quantum Solids throughout the South Korea Institute for Fundamental Science has made vital development in semiconductor and nanomaterial generation that would result in smaller, extra environment friendly generation. , are very tough digital gadgets. The brand new approach can develop “one-dimensional” steel gadgets with a width as slim as 0.4 nanometers to be used as gate electrodes in a 2D layer. This manner guarantees to conquer the constraints of the literature. Built-in gadgets in accordance with two-dimensional semiconductors showcase very good electric houses even if scaled right down to atomic thicknesses, making them promising for the improvement of ultra-thin, high-performance digital gadgets. A little analysis presentations that those 2D sound circles are promising for individuals who will reside within the generation of Moore’s Legislation. On the other hand, the improvement of built-in circuits in accordance with 2D constructions has confronted vital demanding situations. Integrating 2D fabrics into a device with out destroying its fragile construction may be very tricky, and persistently discovering the most productive 2D gadgets is much more tricky.

Any other downside is that the present strategies of quarrying and processing don’t paintings on such small scales. In typical semiconductor production strategies, lowering the gate period under a couple of nanometers isn’t imaginable because of the constraints of lithography answer. You will need to notice that the stage of integration of semiconductor gadgets is made up our minds via the width and potency of the gate electrode, which controls the waft of electrons within the transistor. The crew discovered that the dual limitations of molybdenum disulfide, a 2D semiconductor, and a 1D steel are 0.4 nm in width. He used this as a gate electrode, overcoming the constraints of the lithography procedure. The crew can change into an current 2D semiconductor right into a 1D MTB via controlling the form of the glass on the atomic stage. Those 1D steel constructions can act as gate electrodes in miniaturized steady transistors. “The 1D steel layer got thru epitaxial enlargement is a brand new approach that may be carried out to ultra-miniaturized semiconductor processes,” mentioned Director JO Moon-Ho. “It’s anticipated to be a key generation for the improvement of low cost, high-performance digital gadgets one day.”

Analysis crew creates procedure to develop sub-nanometer transistors

:max_bytes(150000):strip_icc()/GettyImages-2224431457-74c3a364f9fa4b33a0889f2d7b6a770f.jpg)