This text has been reviewed in keeping with Science X’s editorial procedure

and insurance policies.

Editors have highlighted the next attributes whilst making sure the content material’s credibility:

fact-checked

peer-reviewed newsletter

depended on supply

proofread

Good enough!

Samples of a category of ceramics, referred to as high-entropy carbides, which have been engineered to resist extra pressure and tension prior to breaking. Credit score: Liezel Labios/UC San Diego Jacobs College of Engineering

× shut

Samples of a category of ceramics, referred to as high-entropy carbides, which have been engineered to resist extra pressure and tension prior to breaking. Credit score: Liezel Labios/UC San Diego Jacobs College of Engineering

Researchers have found out a method to make ceramics harder and extra immune to cracking. Through development those fabrics the use of a mix of steel atoms possessing extra electrons of their outer shell, a workforce led by way of engineers on the College of California San Diego has unlocked the prospective to allow ceramics to care for upper ranges of pressure and tension than prior to.

Ceramics be offering many benefits because of their outstanding houses, together with their skill to resist extraordinarily excessive temperatures, face up to corrosion and floor put on, and handle light-weight profiles. Those houses lead them to appropriate for plenty of programs equivalent to aerospace elements and protecting coatings for engines and chopping gear. Then again, their weak point has all the time been their brittleness. They spoil simply beneath tension.

However now, researchers have discovered an answer that would make ceramics tougher to wreck. They revealed their paintings lately in Science Advances.

The find out about, led by way of UC San Diego nanoengineering professor Kenneth Vecchio, facilities on a category of ceramics referred to as high-entropy carbides. Those fabrics have extremely disordered atomic buildings, composed of carbon atoms bonded with a couple of steel parts from the fourth, 5th and 6th columns of the periodic desk.

Those metals come with titanium, niobium and tungsten, for instance. The researchers discovered that the important thing to improving ceramic toughness lay in the usage of metals from the 5th and 6th columns of the periodic desk, because of their upper choice of valence electrons.

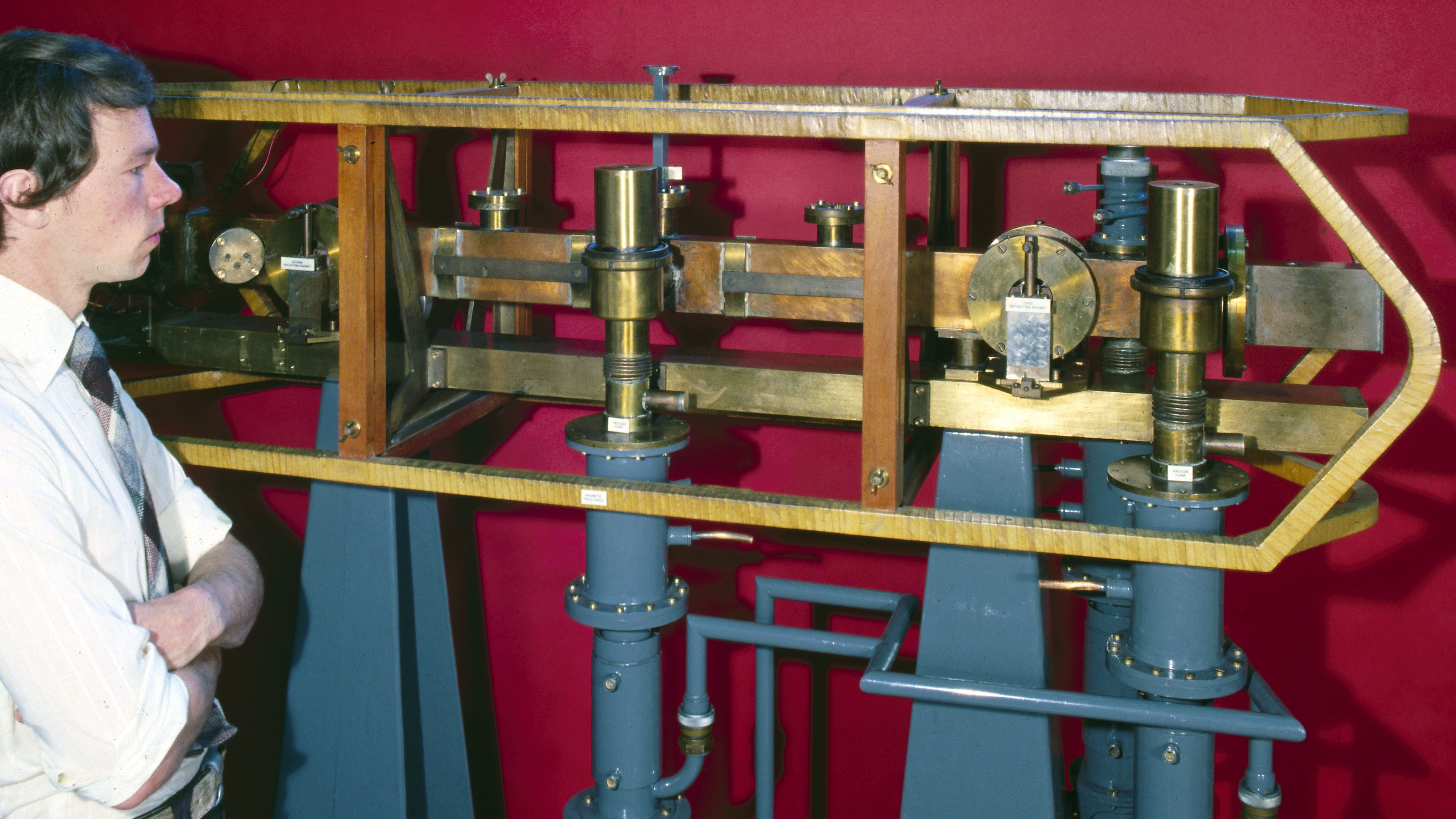

Simulations evaluating the responses beneath implemented tension of ceramics with other valence electron concentrations. Credit score: UC San Diego Jacobs College of Engineering

Valence electrons—the ones dwelling in an atom’s outermost shell and attractive in bonding with different atoms—proved to be a pivotal issue. Through the use of metals with a better valence electron rely, the researchers effectively stepped forward the fabric’s resistance to cracking when subjected to mechanical load and tension.

“The ones further electrons are vital as a result of they successfully make the ceramic subject matter extra ductile, which means it could actually go through extra deformation prior to breaking, very similar to a steel,” mentioned Vecchio.

To raised perceive this impact, Vecchio’s staff collaborated with Davide Sangiovanni, a professor of theoretical physics at Linköping College, Sweden. Sangiovanni carried out the computational simulations, and Vecchio’s workforce experimentally fabricated and examined the fabrics.

The workforce investigated high-entropy carbides that includes more than a few mixtures of 5 steel parts. Each and every mixture yielded a unique focus of valence electrons inside the subject matter.

They known two high-entropy carbides that exhibited outstanding resistance to cracking beneath load or tension, due to their excessive valence electron concentrations. One used to be composed of the metals vanadium, niobium, tantalum, molybdenum and tungsten. The opposite variant substituted niobium with chromium within the combine.

Underneath mechanical load or tension, those fabrics had been in a position to deform or stretch, respectively, similar to the habits of metals reasonably than the everyday brittle reaction of ceramics. As those fabrics had been punctured or pulled aside, bonds started to wreck, forming atom-sized openings.

The extra valence electrons across the steel atoms then reorganized to bridge those openings, forming new bonds between neighboring steel atoms. This mechanism preserved the fabric’s construction across the openings, successfully inhibiting them from rising larger and forming cracks.

“We found out that there is this underlying transformation going down on the nanoscale the place the bonds are being rearranged to carry the fabric in combination,” mentioned find out about co-author Kevin Kaufmann, a UC San Diego nanoengineering Ph.D. alumnus from Vecchio’s lab. “As a substitute of simply cleaving proper around the fracture floor, the fabric slowly frays like a rope would when it’s being pulled. On this approach, the fabric can accommodate this deformation that is happening and now not fail in a brittle way.”

The problem now lies in scaling up the manufacturing of those difficult ceramics for business programs. That would assist change into applied sciences that depend on high-performance ceramic fabrics, from aerospace elements to biomedical implants.

The newfound toughness of those ceramics additionally paves the best way for his or her use in excessive programs, equivalent to main edges for hypersonic cars. Harder ceramics may function frontline protection for those cars, shielding important elements from getting impacted by way of particles and enabling the cars to raised continue to exist supersonic flights, defined Vecchio.

“Through addressing a longstanding limitation of ceramics, we will be able to a great deal increase their use and create next-generation fabrics that hang the prospective to revolutionize our society,” mentioned Vecchio.

Additional info:

Davide G. Sangiovanni et al, Valence electron focus as key parameter to keep watch over the fracture resistance of refractory high-entropy carbides, Science Advances (2023). DOI: 10.1126/sciadv.adi2960

Magazine knowledge:

Science Advances