NASA’s Artemis marketing campaign will ship astronauts, payloads, and science experiments into deep house on NASA’s SLS (House Release Gadget) tremendous heavy-lift Moon rocket. Beginning with Artemis IV, the Orion spacecraft and its astronauts will likely be joined by way of different payloads atop an upgraded model of the SLS, referred to as Block 1B. SLS Block 1B will ship preliminary components of a lunar house station designed to allow long run exploration of the lunar floor and pave the way in which for long run trips to Mars. To fly those complex payloads, engineers at NASA’s Marshall House Flight Heart in Huntsville, Alabama, are development a cone-shaped adapter this is key to SLS Block 1B.

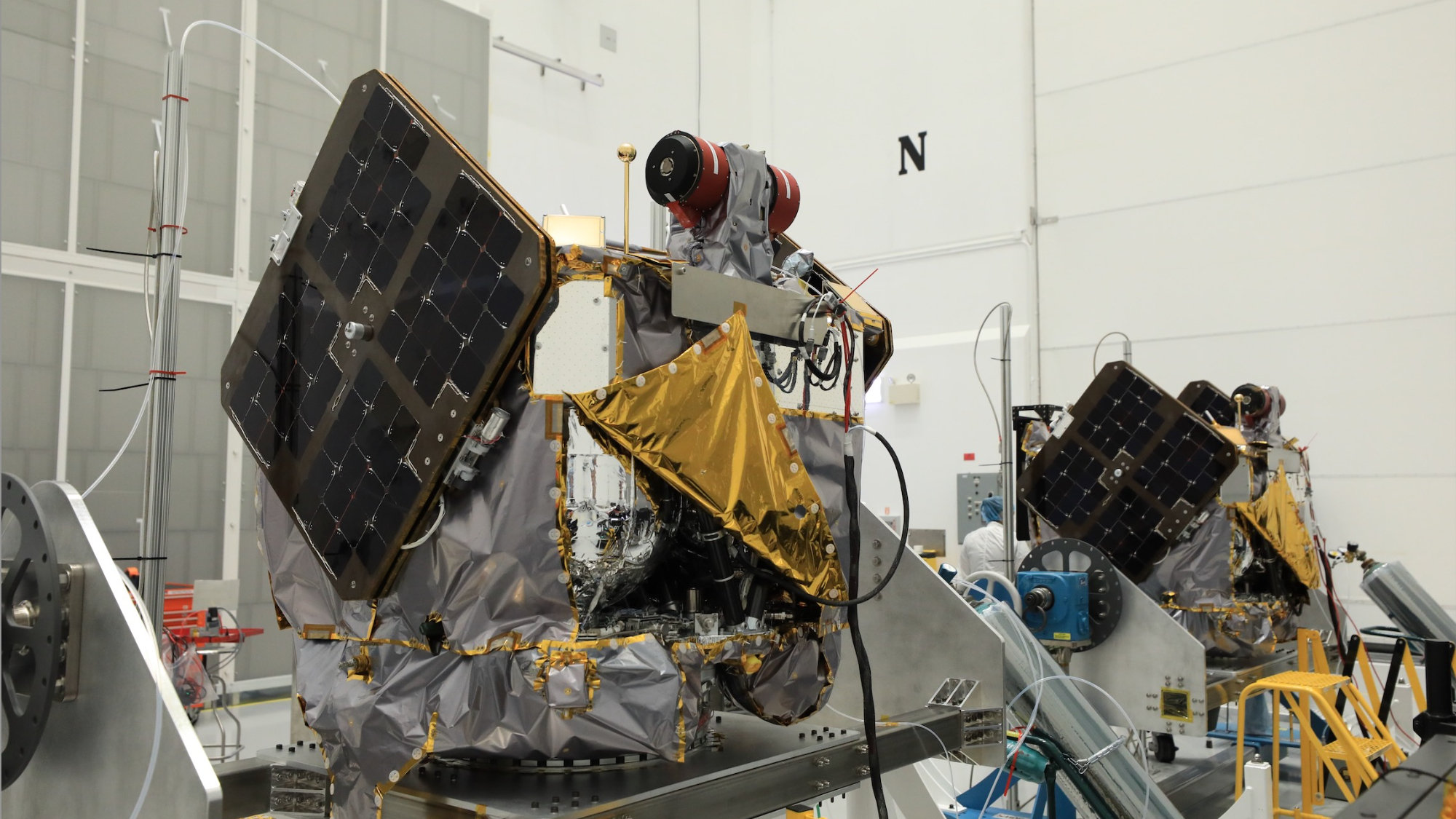

The payload adapter, nestled inside the common level adapter sitting atop the SLS Block 1B’s exploration higher level, acts as a connecting level to safe a big payload this is co-manifested – or flying at the side of – the Orion spacecraft. The adapter is composed of 8 composite panels with an aluminum honeycomb core and two aluminum rings.

Starting with the Artemis IV undertaking, SLS Block 1B will characteristic a brand new, extra tough higher level that gives a considerable build up in payload mass, quantity, and effort over the primary variant of the rocket this is launching Artemis missions I via III. SLS Block 1B can ship 84,000 kilos of payload – together with each a crewed Orion spacecraft and a 10-metric ton (22,046 lbs.) co-manifested payload driving in a separate shipment compartment – to the Moon in one release.

Artemis IV’s co-manifested payload would be the Lunar I-Hab, some of the preliminary components of the Gateway lunar house station. Constructed by way of ESA (Eu House Company), the Lunar I-Hab supplies expanded capacity for astronauts to are living, paintings, habits science experiments, and get ready for his or her missions to the lunar floor.

Sooner than the Artemis IV undertaking construction was once finalized, NASA engineers had to design and check the brand new payload adapter.

“With SLS, there’s an intent to have as a lot commonality between flights as imaginable,” says Brent Gaddes, Lead for the Orion Degree Adapter and Payload Adapter within the SLS Spacecraft/Payload Integration & Evolution Place of business at NASA Marshall.

Alternatively, with the ones payloads converting usually each and every flight, the connecting payload adapter should alternate as neatly.

“We knew there had to be numerous flexibility to the payload adapter, and that we would have liked so to reply temporarily in-house as soon as the payloads have been finalized,” says Gaddes.

The desired flexibility was once no longer going to be happy with a one-size-fits-all way, in line with Gaddes.

Since other length payload adapters may well be wanted, Marshall is the usage of a versatile strategy to collect the payload adapter that removes the will for heavy and costly tooling used to carry the portions in position all the way through meeting. A pc fashion of every finished phase is created the usage of a procedure referred to as structured mild scanning. The pc fashion supplies the proper places the place holes want to be drilled to carry the portions in combination in order that the finished payload adapter will likely be precisely the fitting length.

“Structured mild has helped us scale back prices and build up flexibility at the payload adapter and permits us to pivot,” says Gaddes. “If the decision got here right down to construct a shipment model of SLS to release 40 metric heaps, as an example, we will use our similar tooling with the structured mild strategy to adapt to other sizes, whether or not that’s for an adapter with a bigger diameter that’s shorter, or one with a smaller diameter that’s longer. It’s sooner and less expensive.”

NASA Marshall engineers use an automatic placement robotic to fabricate 8 light-weight composite panels from a graphite epoxy subject material. The robotic plays speedy, correct lamination following preprogrammed paths, its prime velocity and precision leading to cheaper price and considerably sooner manufacturing than different production strategies.

At NASA Marshall, an engineering building unit of the payload has been effectively examined which demonstrated that it could possibly care for as much as 3 times the anticipated load. Every other check model lately in building, referred to as the qualification unit, may also be examined to NASA requirements for composite constructions to make sure that the flight unit will carry out as anticipated.

“The payload adapter is formed like a cone, and traditionally, many of the building paintings on constructions like this has been on cylinders, in order that’s some of the many explanation why checking out it’s so necessary,” says Gaddes. “NASA will check as prime a load as imaginable to be told what produces structural failure. Any knowledge we be told right here will feed immediately into the frame of data NASA has pulled in combination over time on how one can analyze constructions like this, and naturally that’s one thing that’s shared with business as neatly. It’s a win for everyone.”

With Artemis, NASA will discover extra of the Moon than ever earlier than, discover ways to are living and paintings clear of house, and get ready for long run human exploration of the Pink Planet. NASA’s SLS (House Release Gadget) rocket, exploration floor techniques, and Orion spacecraft, at the side of the human touchdown device, next-generation spacesuits, Gateway lunar house station, and long run rovers are NASA’s basis for deep house exploration.

Jonathan Deal

Marshall House Flight Heart, Huntsville, Ala.

256-544-0034

jonathan.e.deal@nasa.gov