This text has been reviewed in keeping with Science X’s editorial procedure

and insurance policies.

Editors have highlighted the next attributes whilst making sure the content material’s credibility:

fact-checked

relied on supply

proofread

Good enough!

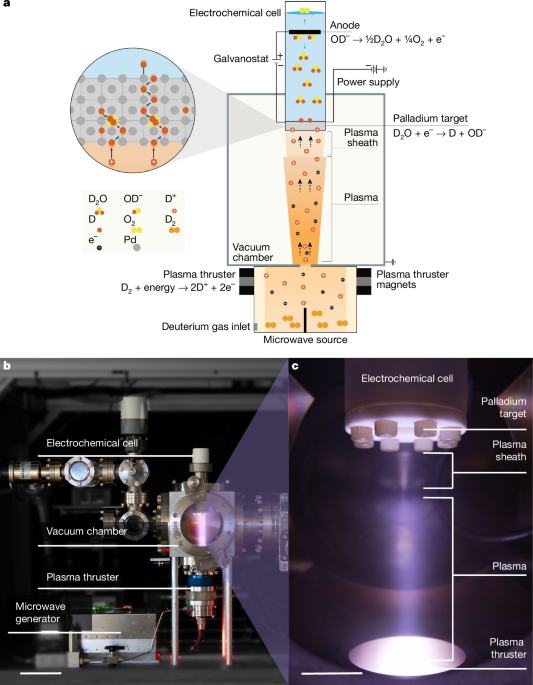

The researchers’ chilly spray tantalum pattern is being uncovered to deuterium plasma throughout checking out at Forschungszentrum Jülich GmbH in Germany. Credit score: Mykola Ialovega

× shut

The researchers’ chilly spray tantalum pattern is being uncovered to deuterium plasma throughout checking out at Forschungszentrum Jülich GmbH in Germany. Credit score: Mykola Ialovega

College of Wisconsin–Madison engineers have used a sprig coating era to provide a brand new workhorse subject material that may resist the tough stipulations within a fusion reactor.

The improvement, detailed in a paper printed lately within the magazine Physica Scripta, may permit extra environment friendly compact fusion reactors which might be more straightforward to fix and take care of.

“The fusion group is urgently in search of new production approaches to economically produce huge plasma-facing elements in fusion reactors,” says Mykola Ialovega, a postdoctoral researcher in nuclear engineering and engineering physics at UW–Madison and lead creator at the paper. “Our era presentations really extensive enhancements over present approaches. With this analysis, we’re the first to reveal the advantages of the usage of chilly spray coating era for fusion packages.”

The researchers used a chilly spray procedure to deposit a coating of tantalum, a steel that may resist prime temperatures, on stainless-steel. They examined their chilly spray tantalum coating within the excessive stipulations related to a fusion reactor and located that it carried out really well. Importantly, they came upon the fabric is outstandingly just right at trapping hydrogen debris, which is really helpful for compact fusion gadgets.

“We came upon that the chilly spray tantalum coating absorbs a lot more hydrogen than bulk tantalum as a result of the original microstructure of the coating,” says Kumar Sridharan, a professor of nuclear engineering and engineering physics and fabrics science and engineering. Over the past decade, Sridharan’s analysis team has offered chilly spray era to the nuclear power group by way of imposing it for more than one packages associated with fission reactors.

“The simplicity of the chilly spray procedure makes it very sensible for packages,” Sridharan says.

In fusion gadgets, plasma—an ionized hydrogen gasoline—is heated to extraordinarily prime temperatures, and atomic nuclei within the plasma collide and fuse. That fusion procedure produces power. On the other hand, some hydrogen ions would possibly get neutralized and break out from the plasma.

From left to proper: Engineer Jeremiah Kirch, postdoctoral researcher Mykola Ialovega and assistant scientist Marcos Xavier Navarro-Gonzalez, who paintings at the implementation of tantalum coatings as a plasma-facing subject material for the WHAM instrument, which is pictured within the background. Credit score: Mykola Ialovega

× shut

From left to proper: Engineer Jeremiah Kirch, postdoctoral researcher Mykola Ialovega and assistant scientist Marcos Xavier Navarro-Gonzalez, who paintings at the implementation of tantalum coatings as a plasma-facing subject material for the WHAM instrument, which is pictured within the background. Credit score: Mykola Ialovega

“Those hydrogen impartial debris motive energy losses within the plasma, which makes it very difficult to maintain a sizzling plasma and feature an efficient small fusion reactor,” says Ialovega, who works within the analysis team of Oliver Schmitz, a professor of nuclear engineering and engineering physics.

That is why the researchers got down to create a brand new floor for plasma-facing reactor partitions that would lure hydrogen debris as they collide with the partitions.

Tantalum is inherently just right at soaking up hydrogen—and the researchers suspected that making a tantalum coating the usage of a chilly spray procedure would spice up its hydrogen-trapping talents much more.

Growing a chilly sprayed coating is fairly like the usage of a can of spray paint. It is composed of propelling debris of the coating subject material at supersonic velocities onto a floor. Upon affect, the debris flatten like pancakes and coat all of the floor, whilst maintaining nanoscale obstacles between the coating debris. The researchers came upon that the ones tiny obstacles facilitate trapping of hydrogen debris.

Ialovega carried out experiments at the lined subject material at amenities at Aix Marseille College in France and Forschungszentrum Jülich GmbH in Germany. All the way through those experiments, he discovered that after he heated the fabric to the next temperature, it expelled the trapped hydrogen debris with out enhancing the coatings—a procedure that necessarily regenerates the fabric so it may be used once more.

“Every other large good thing about the chilly spray manner is that it permits us to fix reactor elements on website by way of making use of a brand new coating,” Ialovega says. “Lately, broken reactor elements continuously wish to be got rid of and changed with an absolutely new phase, which is pricey and time eating.”

The researchers plan to make use of their new subject material within the Wisconsin HTS Axisymmetric Reflect (WHAM). The experimental instrument is beneath building close to Madison, Wis., and can function a prototype for a long term next-generation fusion energy plant that UW–Madison derivative Realta Fusion objectives to broaden. Housed within the Bodily Sciences Laboratory, the WHAM experiment is a partnership between UW–Madison, Massachusetts Institute of Generation and Commonwealth Fusion Programs.

“Making a refractory steel composite with those options of well-controlled hydrogen dealing with blended with erosion resistance and normal subject material resilience is a leap forward for the design of plasma gadgets and fusion power methods,” Schmitz says. “The chance of adjusting the alloy and together with different refractory metals to fortify the composite for nuclear packages is especially thrilling.”

Additional info:

Mykola Ialovega et al, Preliminary find out about on thermal steadiness of chilly spray tantalum coating irradiated with deuterium for fusion packages, Physica Scripta (2023). DOI: 10.1088/1402-4896/ad0098