This text has been reviewed consistent with Science X’s editorial procedure

and insurance policies.

Editors have highlighted the next attributes whilst making sure the content material’s credibility:

fact-checked

peer-reviewed e-newsletter

depended on supply

proofread

Good enough!

Credit score: Nanyang Technological College

× shut

Credit score: Nanyang Technological College

Scientists from NTU Singapore have evolved ultra-thin semiconductor fibers that may be woven into materials, turning them into good wearable electronics. Their paintings has been printed within the magazine Nature.

To create reliably functioning semiconductor fibers, they will have to be versatile and with out defects for solid sign transmission. Alternatively, present production strategies purpose tension and instability, resulting in cracks and deformities within the semiconductor cores, negatively impacting their efficiency and proscribing their construction.

NTU scientists carried out modeling and simulations to know how tension and instability happen all over the producing procedure. They discovered that the problem might be triumph over thru cautious subject material variety and a selected collection of steps taken all over fiber manufacturing.

They evolved a mechanical design and effectively fabricated hair-thin, defect-free fibers spanning 100 meters, which signifies its marketplace scalability. Importantly the brand new fibers will also be woven into materials the use of present strategies.

To reveal their fibers’ top of the range and capability, the NTU analysis workforce evolved prototypes. Those incorporated a wise beanie hat to lend a hand a visually impaired individual go the street safely via receiving indicators on a cell phone software; a blouse that receives knowledge and transmits it thru an earpiece, like a museum audio information; and a smartwatch with a strap that purposes as a versatile sensor that conforms to the wrist of customers for center price dimension even all over bodily actions.

Credit score: Nanyang Technological College

The workforce believes that their innovation is a basic step forward within the construction of semiconductor fibers which might be ultra-long and sturdy, which means they’re cost-effective and scalable whilst providing superb electric and optoelectronic (which means it may well sense, transmit and engage with gentle) efficiency.

NTU Affiliate Professor Wei Lei on the College of Electric and Digital Engineering (EEE) and lead-principal investigator of the find out about stated, “The a hit fabrication of our top of the range semiconductor fibers is due to the interdisciplinary nature of our workforce.

“Semiconductor fiber fabrication is a extremely advanced procedure, requiring technology from fabrics science, mechanical, and electric engineering mavens at other phases of the find out about.

“The collaborative workforce effort allowed us a transparent working out of the mechanisms concerned, which in the long run helped us free up the door to defect-free threads, overcoming a long-standing problem in fiber generation.”

Creating semiconductor fiber

To broaden their defect-free fibers, the NTU-led workforce decided on pairs of not unusual semiconductor subject material and artificial subject material—a silicon semiconductor core with a silica glass tube and a germanium core with an aluminosilicate glass tube. The fabrics had been decided on in line with their attributes that complemented every different.

Those incorporated thermal steadiness, electric conductivity, and the facility to permit electrical present to glide thru (resistivity).

Silicon was once decided on for its skill to be heated to top temperatures and manipulated with out degrading and for its skill to paintings within the visual gentle vary, making it excellent to be used in units intended for excessive prerequisites, reminiscent of sensors at the protecting clothes for firefighters.

Germanium, alternatively, permits electrons to transport during the fiber temporarily (service mobility) and paintings within the infrared vary, which makes it appropriate for programs in wearable or fabric-based (i.e., curtains, tablecloth) sensors which might be suitable with indoor Mild constancy (“LiFi”) wi-fi optical networks.

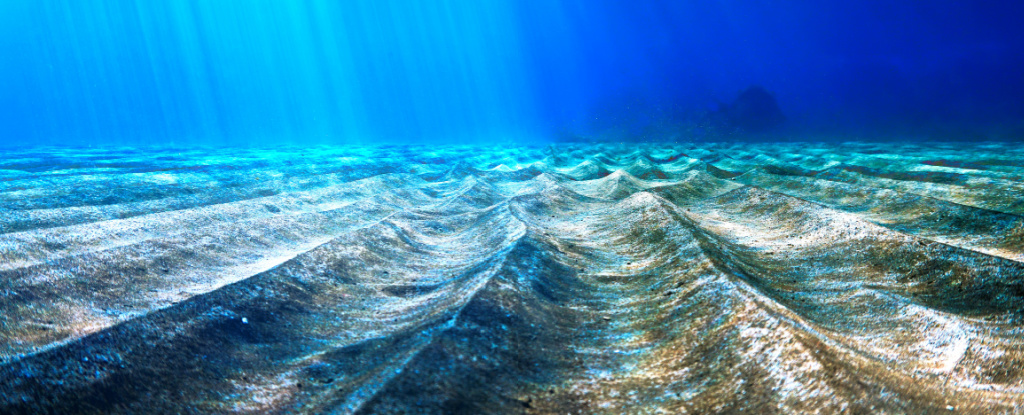

Subsequent, the scientists inserted the semiconductor subject material (core) throughout the glass tube, heating it at top temperature till the tube and core had been comfortable sufficient to be pulled into a skinny steady strand (see symbol underneath).

Because of the other melting issues and thermal growth charges in their decided on fabrics, the glass functioned like a wine bottle all over the heating procedure, containing the semiconductor subject material which, like wine, fills the bottle, because it melted.

First writer of the find out about Dr. Wang Zhixun, Analysis Fellow within the College of EEE, stated, “It took in depth research sooner than touchdown on the right mix of fabrics and procedure to broaden our fibers. By way of exploiting the other melting issues and thermal growth charges of our selected fabrics, we effectively pulled the semiconductor fabrics into lengthy threads as they entered and exited the heating furnace whilst fending off defects.”

The glass is got rid of as soon as the strand cools and mixed with a polymer tube and steel wires. After every other spherical of heating, the fabrics are pulled to shape a hair-thin, versatile thread.

In lab experiments, the semiconductor fibers confirmed superb efficiency. When subjected to responsivity checks, the fibers may stumble on all of the visual gentle vary, from ultraviolet to infrared, and robustly transmit indicators of as much as 350 kilohertz (kHz) bandwidth, making it a best performer of its sort. Additionally, the fibers had been 30 occasions harder than common ones.

The fibers had been additionally evaluated for his or her washability, through which a material woven with semiconductor fibers was once wiped clean in a washer 10 occasions, and effects confirmed no vital drop within the fiber efficiency.

Co-principal investigator, Prominent College Professor Gao Huajian, who finished the find out about whilst he was once at NTU, stated, “Silicon and germanium are two broadly used semiconductors that are generally regarded as extremely brittle and vulnerable to fracture.

“The fabrication of ultra-long semiconductor fiber demonstrates the chance and feasibility of creating versatile elements the use of silicon and germanium, offering in depth house for the advance of versatile wearable units of more than a few paperwork.

“Subsequent, our workforce will paintings collaboratively to use the fiber production strategy to different difficult fabrics and to find extra situations the place the fibers play key roles.”

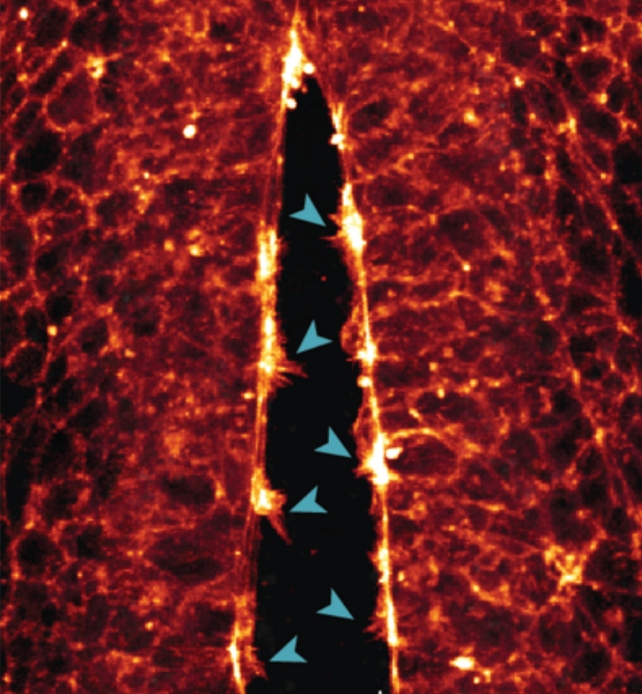

A schematic diagram of the semiconductor fiber production means evolved via the NTU analysis workforce. Credit score: Nanyang Technological College

× shut

A schematic diagram of the semiconductor fiber production means evolved via the NTU analysis workforce. Credit score: Nanyang Technological College

Compatibility with trade’s manufacturing strategies hints at simple adoption

To reveal the feasibility of use in real-life programs, the workforce constructed good wearable electronics the use of their newly created semiconductor fibers. Those come with a beanie, a sweater, and an eye fixed that may stumble on and procedure indicators.

To create a tool that assists the visually impaired in crossing busy roads, the NTU workforce wove fibers right into a beanie hat, along side an interface board. When examined experimentally outdoor, gentle indicators gained via the beanie had been despatched to a cell phone software, triggering an alert.

A blouse woven with the fibers, in the meantime, functioned as a “good best,” which might be worn at a museum or artwork gallery to obtain details about reveals and feed it into an earpiece because the wearer walked across the rooms.

A smartwatch with a wristband built-in with the fibers functioned as a versatile and conformal sensor to measure center price, versus conventional designs the place a inflexible sensor is put in at the frame of the smartwatch, which might not be dependable in cases when customers are very lively, and the sensor isn’t involved with the surface.

Additionally, the fibers changed cumbersome sensors within the frame of the smartwatch, saving house and releasing up design alternatives for slimmer watch designs.

Co-author Dr. Li Dong, a Analysis Fellow within the College of Mechanical and Aerospace Engineering, stated, “Our fiber fabrication means is flexible and simply followed via trade. The fiber may be suitable with present textile trade equipment, which means it has the possibility of large-scale manufacturing.

“By way of demonstrating the fibers’ use in on a regular basis wearable pieces like a beanie and an eye fixed, we turn out that our analysis findings can function a information to making purposeful semiconductor fibers someday.”

For his or her subsequent steps, the researchers are making plans to increase the forms of fabrics used for the fibers and get a hold of semiconductors with other hole cores, reminiscent of oblong and triangular shapes, to increase their programs.

Additional info:

Zhixun Wang et al, Top quality semiconductor fibres by the use of mechanical design, Nature (2024). DOI: 10.1038/s41586-023-06946-0

Magazine knowledge:

Nature