In a serendipitous discovery, researchers have created a brand new magnificence of fabrics referred to as ‘glassy gels’ which might be part liquid however exhausting to wreck.Stretchy, surprisingly adhesive, and in a position to ‘self-heal’ if lower, the unexpected houses of those gels probably cause them to helpful for a much wider vary of programs than commonly-used plastics, that are both exhausting and brittle or comfortable and simply torn.

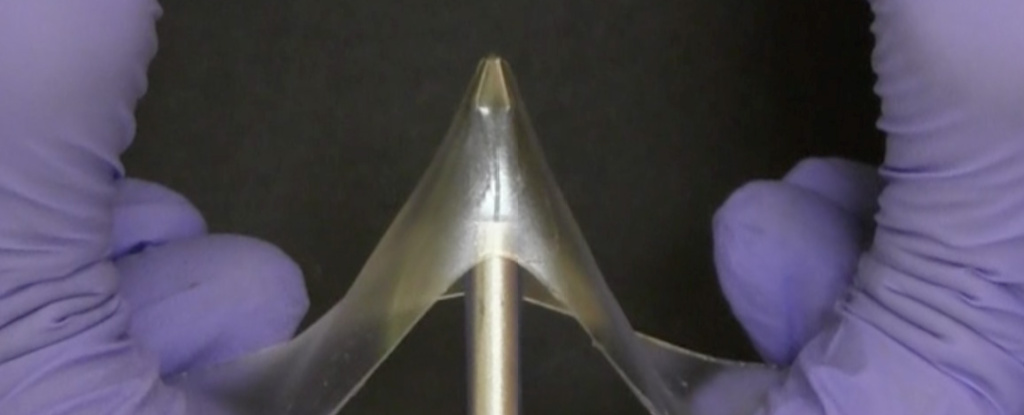

“We’ve got created a category of fabrics that we now have termed glassy gels, that are as exhausting as glassy polymers, however – when you practice sufficient drive – can stretch as much as 5 instances their authentic duration, somewhat than breaking,” says Michael Dickey, fabrics scientist at North Carolina State College (NCSU).

However as with such a lot of fortuitous medical discoveries, the function was once by no means to make an entire new magnificence of subtances, Dickey tells ScienceAlert.

“We stumbled into those attention-grabbing fabrics,” he says, when NCSU researcher Meixiang Wang was once experimenting with ionogels, fabrics product of a polymer swollen with an ionic liquid that conducts electrical energy.

Wang was once seeking to make stretchable, wearable units that may well be utilized in a drive sensor, different scientific units or robotics. Changing the composition, Wang produced a gel that regarded in the beginning like a “mundane piece of clear, versatile plastic” earlier than trying out confirmed it was once very exhausting – however now not brittle like different commonplace plastics.

“When we learned they’ve outstanding houses, we dove in to know them higher,” Dickey says.

The glassy gels are made the use of an ionic liquid, which is analogous to water however made totally of charged debris, permitting it to habits electrical energy. When combined with a polymer precursor the liquid pushes the polymer chains aside, making the fabric comfortable and stretchy. On the identical time, the ions also are strongly drawn to the polymer chains, combating them from isolating.

“The result is that the fabric is tricky because of the sexy forces, however remains to be in a position to stretching because of the additional spacing,” explains Dickey. frameborder=”0″ permit=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” referrerpolicy=”strict-origin-when-cross-origin” allowfullscreen>The glassy gels do not dry out, even supposing they encompass between 50 to 60 p.c liquid, and trying out confirmed they’ve “monumental” fracture energy and toughness.

The fabric too can ‘self-heal’, reforming if lower, and has one of those reminiscence that permits a stretched gel to carry its form, most effective to contract to its authentic shape when heated.

Even though bizarre, such regenerative houses are not in particular new, particularly in stretchy gel-like fabrics. Just lately, scientists have succeeded on the a lot tougher job of creating in most cases inflexible fabrics, akin to metals, glass, sun panels and urban that heal when cracked. If commercialized, fabrics like those, in a position to repairing themselves when broken, may assist to cut back waste, within the development, electronics, and style industries.

However the extraordinary mixture of the glassy gels’ outstanding nature is one thing researchers wish to discover additional.

“Possibly probably the most intriguing feature of the glassy gels is how adhesive they’re,” Dickey says. “We perceive what makes them exhausting and stretchable, [but] we will most effective speculate about what makes them so sticky.”

Extra trying out and optimization of the ‘gel’ is clearly required earlier than those gels can be utilized in any sensible manner, however occupied with doable programs, Dickey says difficult fabrics that habits electrical energy (just like the gel does) are helpful in batteries.

Different doable makes use of come with three-D printing plastic-like fabrics the use of more effective ways than melt-processing – the process recently used to provide business plastics from starter resins. This procedure steadily comes to transport merchandise to more than one amenities for each and every step of plastic manufacturing, while the glassy gels may also be injected right into a mildew and cured with UV gentle.

However earlier than running against programs, Dickey says his staff needs to higher perceive the fundamentals of the way those fabrics shape, and why there appears to be a ‘magic ratio’ of solvent to polymer that creates the gels’ distinctive houses.

“Taking into consideration the choice of distinctive houses they possess, we are positive that those fabrics will likely be helpful,” Wang says.The find out about has been printed in Nature.

This Glassy Gel Is a Unexpected New Magnificence of Subject material That Heals Itself