Testing 3D printers is a meticulous process. Publishers often employ different tools and techniques to create samples. I evaluate both SLA (resin-based) printers and FDM (plastic-melting) printers, each with its own unique methodology. I consider the following criteria when selecting the best candidates:

- Hardware quality

- Installation ease

- Embedded software

- Seal appearance and accuracy

- Preparation

- Corporate and community support

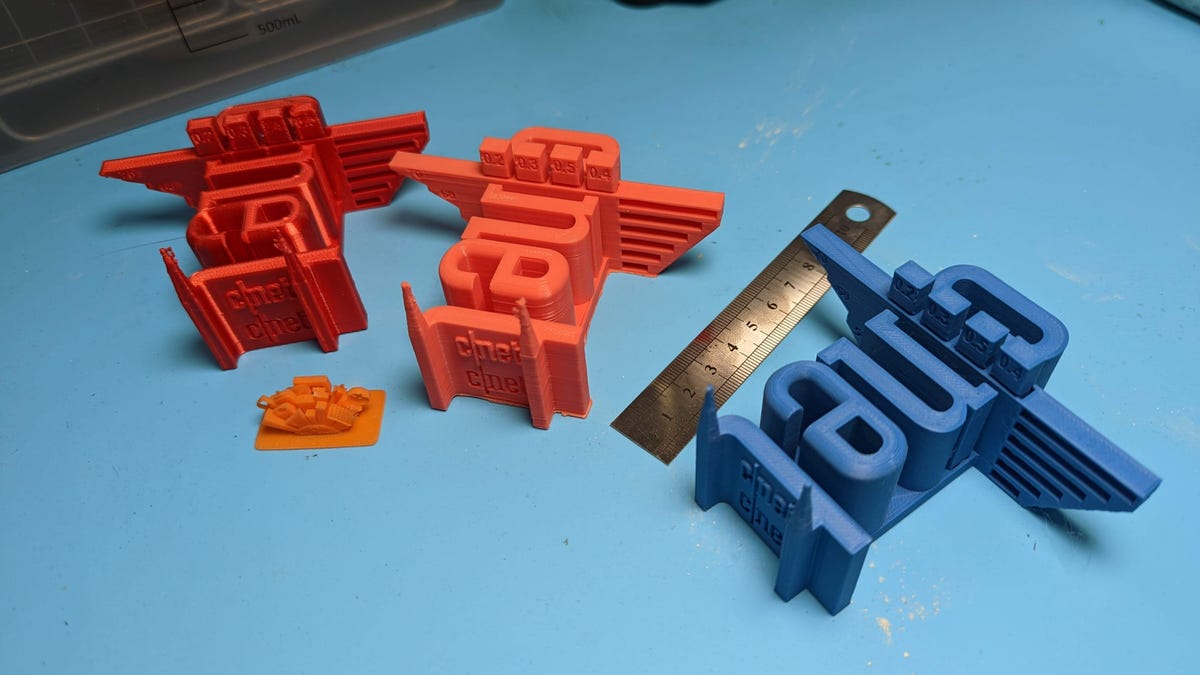

A large test printer, resembling the (old) CNET logo, is used to assess its ability to close gaps, create accurate shapes, and handle overhangs. It also features a small platform to gauge the printer’s response to heat.

When evaluating speed, we slice a sample using the printer’s default settings and compare the actual print time with the estimated completion time provided by the machine. Different slicers and cutters may yield varying estimates. To determine the printer’s speed in millimeters per second (mm/s), we utilize PrusaSlicer to calculate the material consumption and divide it by the actual print time.

Each building block must be heated to a specific temperature. We utilize the InfiRay thermal imaging camera for Android to assess their performance. The build plate is set to 60 degrees Celsius, a common temperature, and we wait 5 minutes for the temperature to stabilize. Then, we measure the temperature at six different points and calculate the average temperature to evaluate how closely the 3D printer matches the advertised temperature.

When testing resin-based printers, I employ the AmeraLabs test, which involves printing a small resin model resembling a tiny town. This helps assess the printer’s accuracy, its capability to handle small particles, and how UV light interacts with different parts of the sample.

Many more test prints, utilizing various 3D models, are performed on each printer to evaluate part length and the machine’s performance with different shapes.

In addition, I research the company to evaluate its responsiveness to customer support inquiries and the ease of ordering and installing replacement parts. For kits (partially assembled printers), I consider the assembly process’s complexity, length, and clarity of instructions.

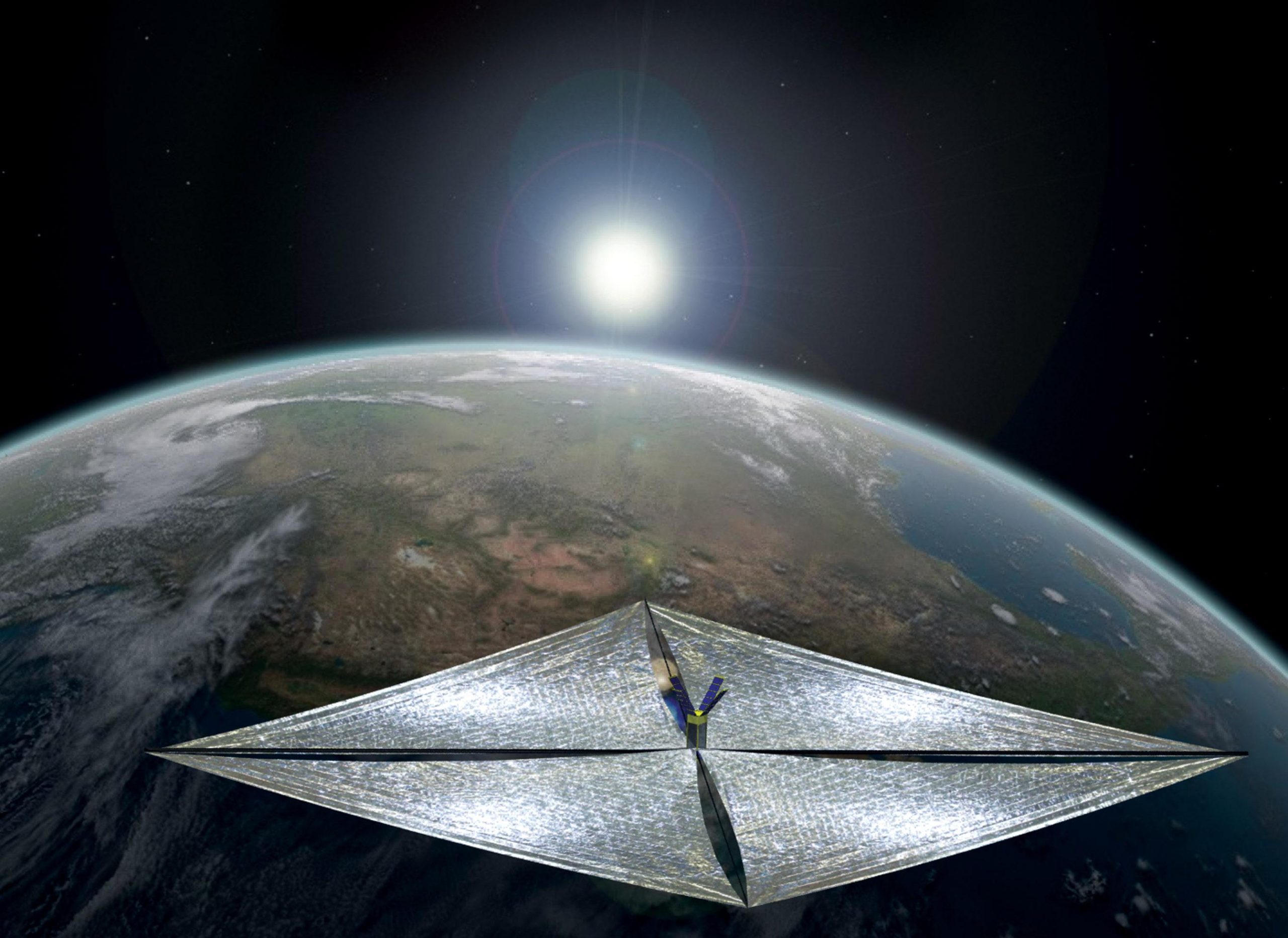

Scientists are creating two experimental propulsion strategies—nuclear fusion

Scientists are creating two experimental propulsion strategies—nuclear fusion